By Mary Hull

We custom mill all kinds of hardwood and pine wide plank floors to fit your look and unique style -whether the place you call home is a vintage farmhouse, a brand new home, or an urban apartment, we can make you the perfect floor. Use this style guide to inspire ideas for your next project.

Rustic

Wood with rustic character works well for a variety of spaces – it is a natural fit for log and timber homes, and it’s also great in modern interiors where it serves as the perfect foil for white spaces and sleek surfaces like glass, metal, and tile.

- Wood floors are an essential design element, comprising the largest visible surface area in your home. Think of them as functional art and embrace the one-of-a-kind look that comes from wood with natural character.

- Wood with natural character adds a warm, organic element to any interior.

- Our best-selling rustic wood floors are in the natural character grades of live sawn white oak, hickory, and ash. Some people may think of character marks as imperfections, but we think they make the most interesting and beautiful wood floors.

Modern to Contemporary

From mid-century modern to the present day and future, if your interior is informed by modernism, we have some ideas for wood floors that will complement your style.

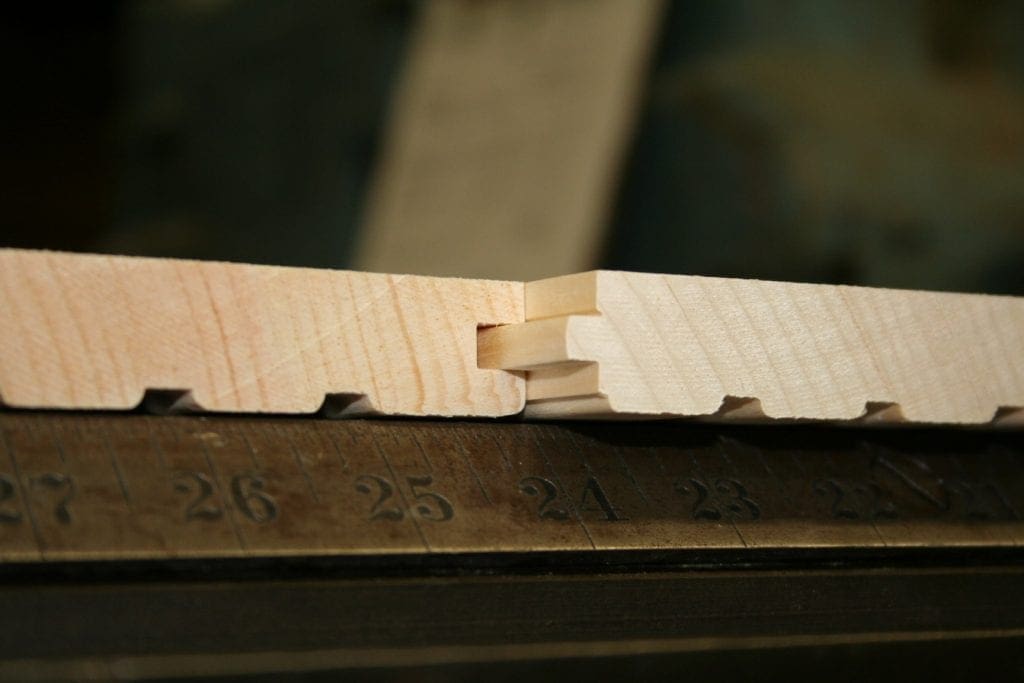

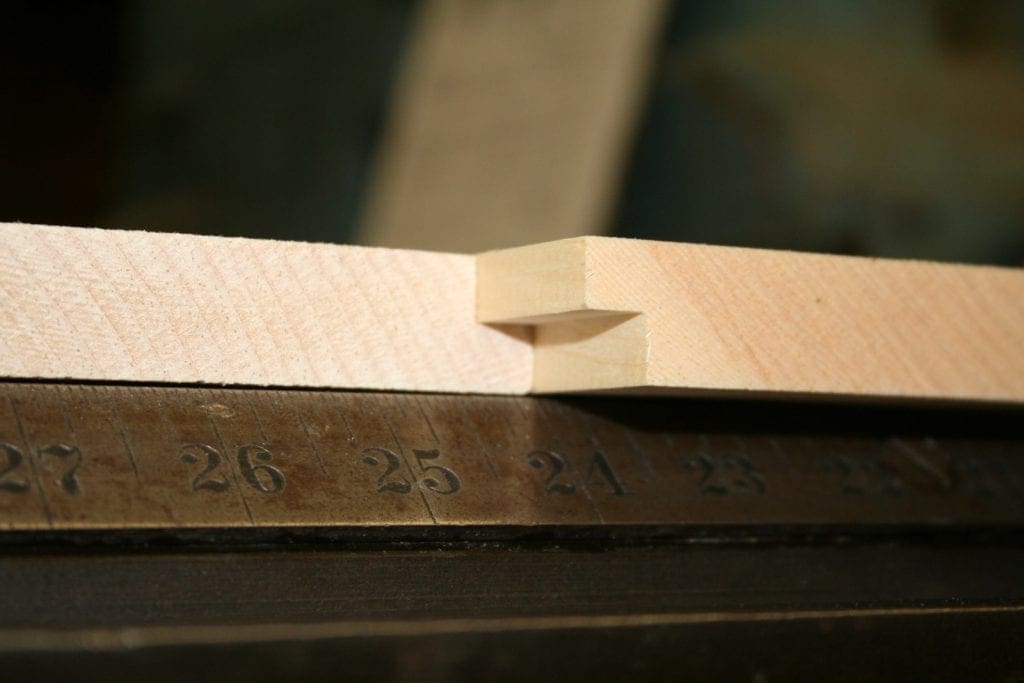

- Planks featuring various curated widths, for example a mix of 5″, 6″, and 7″ face widths, instead of typical all 5″ widths, can create a bespoke look that indicates the flooring is custom made. Planks of all one width can also be used to give off a modern vibe.

- Long planks mean fewer visible seams on the floor, enhancing the sense of flow in open floor plans, particularly when the same species and style is used throughout. The flow is further enhanced with matching stairs.

- We see our wide plain sawn white oak, red oak, ash, and maple going into modern and contemporary spaces, often with a stain to make the wood look a particular way.

Traditional

Have a vintage or traditional home? We can make floors to mimic historic milling techniques, and our random width /random length wide plank floors evoke an earlier time.

- It doesn’t get any more traditional than old fashioned wide plank wood flooring.

- Long and wide planks & random widths are often associated with historic homes. In the old days, when all logs were sawn locally, people used the entire resource as it came off the log, and they would not have had floors that were all one width, or even all one grade. Rather, they had boards in a mix of grades. Our live sawn white oak is a great example of this kind of flooring.

- We see a lot of our varied width flooring, especially live sawn white oak, going into antique, reproduction, and farmhouse style homes. Because live sawn white oak is a mix of several grades and available in a wide range of widths (varied as well as single widths) it is a good fit for many different interiors.

Classic to Transitional

Classic tried and true hardwood flooring enhances your home’s resale value, works with a wide variety of decorating styles, and will look just as timeless in the future as it does today. The transitional style is a classic look that appeals to those seeking middle ground – it can be less formal than traditional style and less austere than contemporary style. Transitional style takes elements from the past and the present and mixes them together for a clean aesthetic that prioritizes comfort.

- Red oak is a classic choice, available in select, premium, and natural grades with plank widths from 3-12 inches and very long plank lengths of 4-12 feet with an average plank length of 7+ feet. Red oak takes stain easily, allowing for a wide range of finish tones, and red oak is less expensive than white oak. Red Oak is also rapidly renewable, making it one of the most environmentally conscious woods you can choose.

- White oak is another classic choice. Those looking to save money are often drawn to the natural live sawn cut of white oak. When the design leans toward a farmhouse vibe, live sawn white oak is a very popular choice.

- We see a lot of our select and premium grades of red oak, white oak , ash, and maple going into transitional style homes.

Browse more of our flooring photos to get inspired. Ready for your customized quote? Click below or call us at 1-800-928-9602 .